Filter the results

Showing 37–42 of 160 results

Wafer / lug type butterfly valve

The TTV centric flanged / double flanged butterfly valve is available in a wide range of materials.

Depending on the application, the seats are available in the most common material EPDM or NBR, but also in different types of silicone, Hypalon, Nordel, Viton and many others.

Suitable for all industries and the most diverse applications due to the different choice of seats.

Depending on the application, available in the most common material EPDM or NBR and in different types of silicone, Hypalon, Nordel, Viton and many others.

Dual plate check valve

The ChemValve Schmid dual plate check valve has an eccentric disc and a wafer design.

The flow-friendly design reduces the pressure loss in the system and therefore the energy requirements of the plant.

Another advantage of this valve is that no gland is required due to the design and so it is impossible for the medium to escape.

The dual plate check valve is used in all industrial processes involving liquids, gases or steam.

Digital (electro-pneumatic) positioner

The Digital (electro-pneumatic) positioner TZID-C from ABB is an electronically parametrisable and communication-enabled positioner for mounting on pneumatic linear and part-turn actuators.

It is characterised by a small, compact modular design and an excellent price-performance ratio. The adjustment to the actuator and the determination of the control parameters are performed fully automatically, thus achieving the greatest possible time savings and optimum control behaviour.

Digital (electro-pneumatic) positioner EDP300

The digital (electro-pneumatic) positioner EDP300 from ABB is an electronically parametrisable and communication-enabled positioner for mounting on pneumatic linear and part-turn actuators.

It is characterised by a small, compact modular design and an excellent price-performance ratio.

The adjustment to the actuator and the determination of the control parameters are performed fully automatically, thus achieving the greatest possible time savings and optimum control behaviour. It has a wide range of diagnostic possibilities as well as option modules and enhancements.

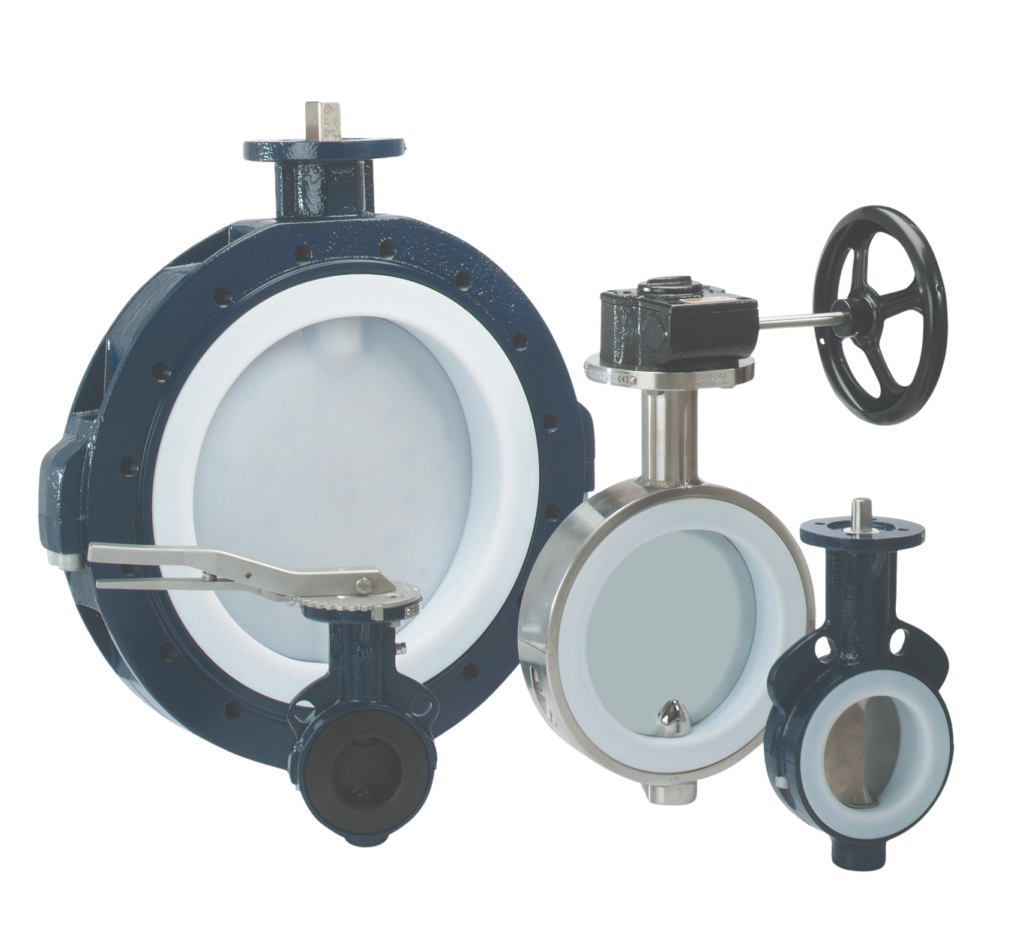

PTFE lined butterfly valve

The ChemValve-Schmid butterfly valve CST is the world’s leading modular PTFE lined butterfly valve.

The PTFE lined valve is produced to the highest quality standards for the safe handling of aggressive media. It is designed for the use with highly chemical media and is therefore used in almost all industries.

Spherical structural elements reduce friction and therefore increase the service life.