Filter the results

Showing 85–90 of 160 results

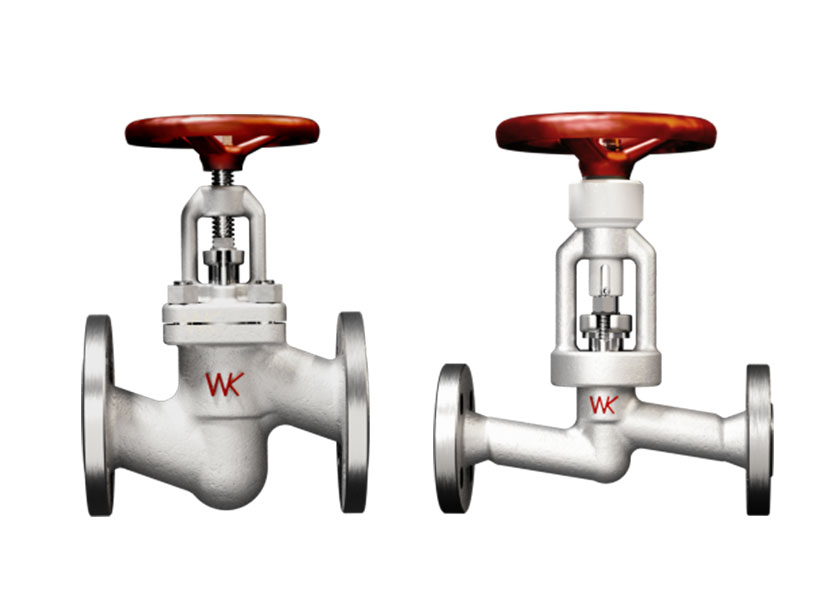

DIN on/off and control globe valve, forged with gland seal or bellows seal

“The Wakmet metal seated (Type 218 / 218R / 218M / 412 / 422 / 412M / 422M / 530 / 530M / 648M / 649M) globe and regualting valves made of forged steel with a gland or bellows seal, have a one-piece housing and are available with or without a control cone.

The monolithic design allows 100% tightness in both flow directions. The valves are mainly used in the energy sector as well as in various areas in the pulp and paper industry.

DIN piston check valve

“LDM piston check valves are self-acting valves to prevent unwanted backflows. They are designed for long-term and maintenance-free operation.

Depending on the version, the valves are closed by the weight or by an additional spring.

These models are also available in oil and grease-free versions.

Nominal diameters from DN15 – DN200

Nominal pressure PN16-PN40

Temperature range of -10°C to +400°C

“

DIN strainer

“The flanged strainers FP 110, 210, 220, 230 are pipe elements to clean mechanical impurities out of the medium.

The strainers excel with a robust body construction made of stainless steel and the possibility to clean the media without having to dismantle the bonnet.

The LDV Valves DIN strainer valves are designed with an angle seat and a flange connection.

The strainer valves are available in different mesh sizes and lengths according to DIN 558-1 GR 1.

Depending on the type, different housing materials are available such as GG25, GGG40, 1.0619, 1.4581 and others are available on request. The strainer material is stainless steel.

ATEX, TA-Luft certificates as well as oil and grease-free versions are available on request.”

DIN strainer, forged

Wakmet strainer valves made of forged steel reliably protect pipes and components from contamination and damage.

Wakmet strainer valves can be supplied with a drain plug on request.

Depending on the model, the temperature ranges extend up to 530°C (up to ≤ 200°C for PTFE).

The Wakmet metal seated DIN strainer valves (Type 822/ 823/ 912/ 922/ 932) are mainly used in the energy sector as well as in the pulp and paper industry.

Depending on the type, they are suitable for media such as water, steam, acids, alkalis, non-aggressive and non-toxic media as well as some also for gas, fuel and sea water.

DIN swing check valve, forged

Wakmet check valves prevent the backflow of medium into the pipe.

The forged welded design prevents material defects such as cracks or porosity and excludes non-metallic impurities.

A completely open disc provides a full bore so the flow rate remains unaffected. A version with a bypass valve is available on request.

The metal seated DIN check valves KZS/KZK are mainly used in the energy sector for energy applications as well as in the pulp and paper industry.