Filter the results

Showing 115–120 of 160 results

Needle valve

On/off and control butterfly valves

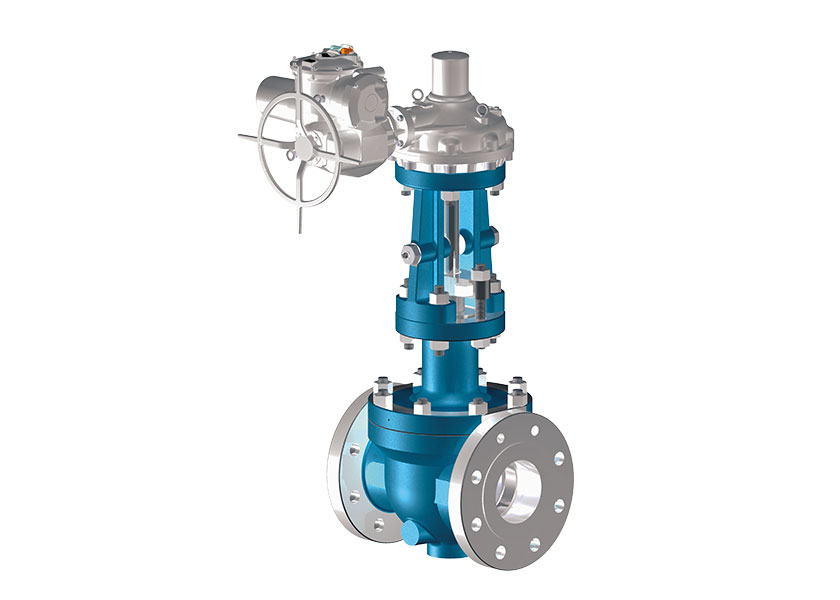

The throttle valves HRD and HRA are designed as a wafer type valve with a centric valve disc.

Depending on the choice of material, they are designed for operating temperatures up to 1050°C. In the high-temperature version, they have a welded wafer type housing or a one-piece housing.

The throttle valves are suitable for valves according to DIN EN 1092-1 or ASME B16.5 / ASME B16.47, with lengths according to DIN EN 558-1-R20, as well as from DN400 according to the company standard.

The connecting flange is for actuators according to DIN EN ISO 5211.

Testing according to DIN EN 12266.

SIL approval according to ICE 61508 and ICE 61511

Versions:

HRD without seat (leakage approx. 1% of surface equivalent),

HRA metal seated (leakage approx. 0.5% of surface equivalent), HRA with seal ring (leakage approx. 0.3% of surface equivalent),

HRA with metal travel stop ring with seal ring (leakage approx. 0.1% of surface equivalent)