Filter the results

Showing 73–78 of 160 results

Digital positioner

“The Sipart PS2 is an electronically parametrisable and communication-enabled positioner for mounting on pneumatic linear and part-turn actuators. It is characterised by a small, compact modular design.

The adjustment to the actuator and the determination of the control parameters are performed fully automatically, thus achieving the greatest possible time savings and optimum control behaviour. It has a wide range of diagnostic possibilities as well as option modules and enhancements.”

DIN flanged ball valve with heating jacket, long pattern, floating

DIN flanged ball valve, semi trunnion, long/short pattern series

DIN gate valve, small body metal seat

The BFE (Bonney Forge) metal seated, small shut-off gate valve has an outside screwed rising stem, solid wedge and flange connection.

The gate valves are forged and used for non-aggressive liquids, steam and gas.

DIN on/off and control globe valve

“Shut-off control valve with a pressure balanced cone (from DN200), linear flow characteristics and a position indicator.

Available with a gland seal or bellows seal.

The valve can optionally be designed with a control cone or without oil and grease.

For nominal diameters from DN15 – DN400.

Can be used in temperature ranges of -60°C to +550°C depending on the choice of material. “

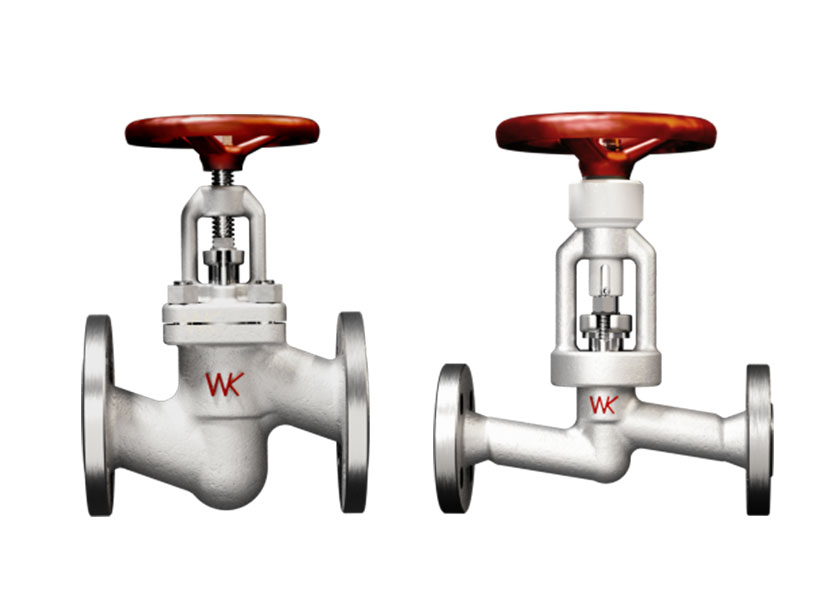

DIN on/off and control globe valve, forged with gland seal or bellows seal

“The Wakmet metal seated (Type 218 / 218R / 218M / 412 / 422 / 412M / 422M / 530 / 530M / 648M / 649M) globe and regualting valves made of forged steel with a gland or bellows seal, have a one-piece housing and are available with or without a control cone.

The monolithic design allows 100% tightness in both flow directions. The valves are mainly used in the energy sector as well as in various areas in the pulp and paper industry.