Filter the results

Showing 25–30 of 160 results

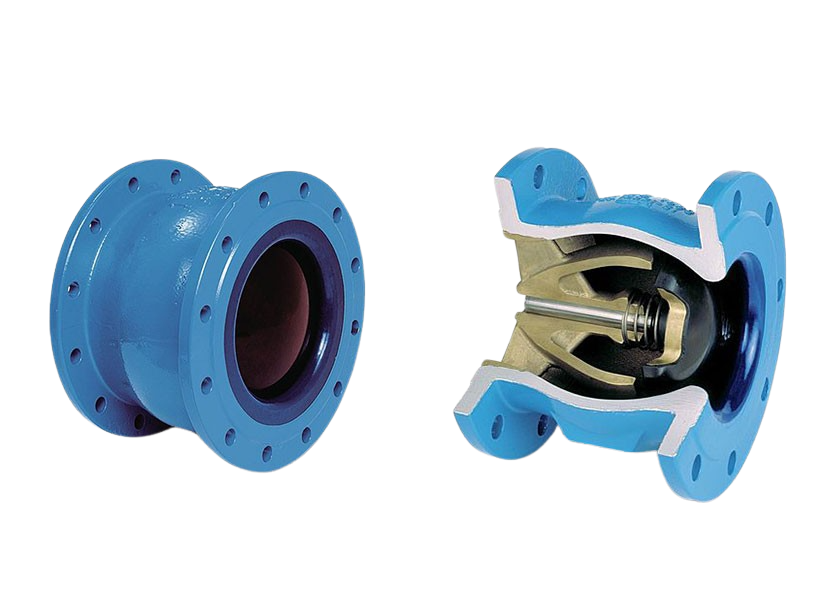

Non slam nozzle check valve

ERHARD nozzle check valves are designed for universal use and are particularly economical check valves for untreated and potable water as well as purified waste water due to their design.

Special features include the ultra-low pressure loss due to optimised flow cross-sections, a flow-efficient valve disc and valve stem gasket, as well as optimum hydraulic behaviour with short closing travel to minimise pressure surges.

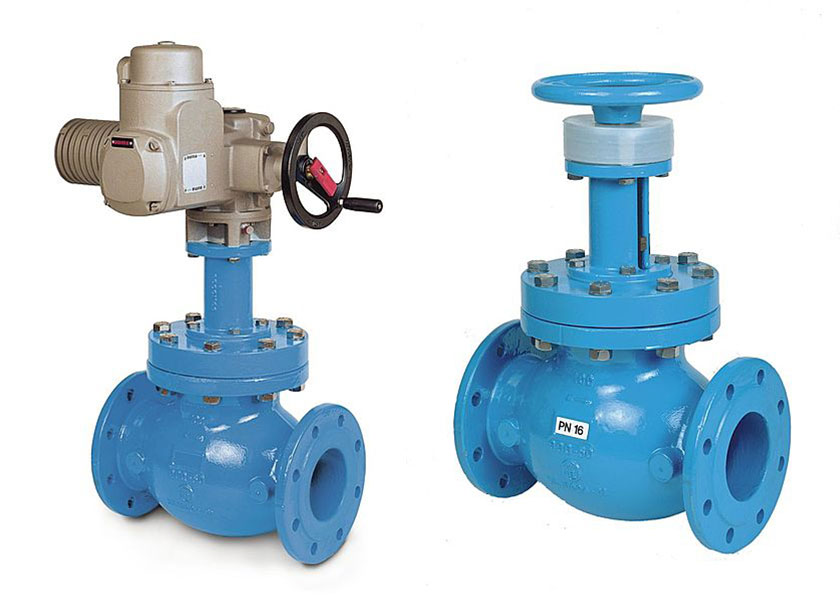

Control valve

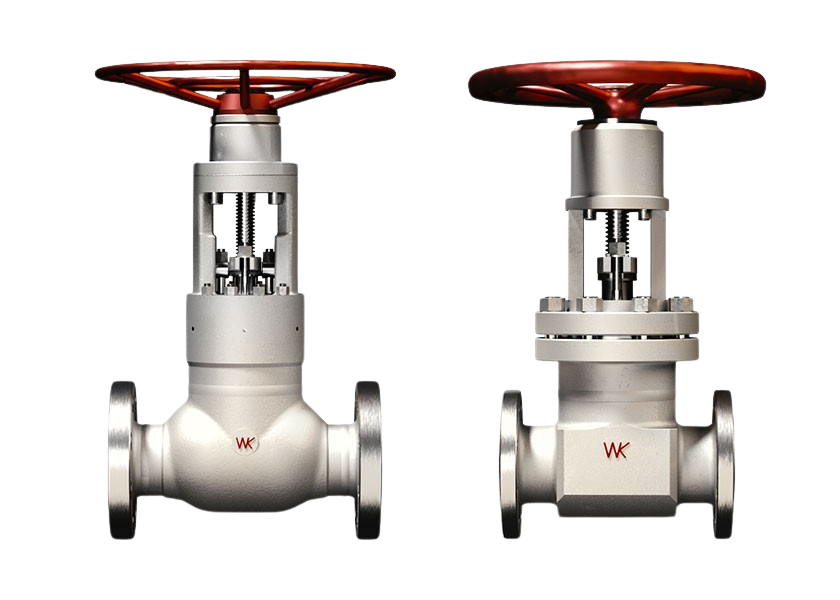

DIN high pressure, double plate wedge gate valve

The forged welded design of the metal seated DIN high-pressure gate valves are made of forged steel with a gland seal or bellows seal prevents material defects such as cracks or porosity.

This type of design ensures that non-metallic impurities are eliminated or excluded.

Wakmet protects the valve against overpressure with a safety valve unit. This type of construction allows easier isolation of the gate valve and direct access to the preset safety valve.

Axial bearing for easier opening/closing of the valve.

This valve is mainly used in the energy sector and in the area of the pulp and paper industry.

Wafer / lug type butterfly valve

The TTV centric flanged / double flanged butterfly valve is available in a wide range of materials.

Depending on the application, the seats are available in the most common material EPDM or NBR, but also in different types of silicone, Hypalon, Nordel, Viton and many others.

Suitable for all industries and the most diverse applications due to the different choice of seats.

Depending on the application, available in the most common material EPDM or NBR and in different types of silicone, Hypalon, Nordel, Viton and many others.

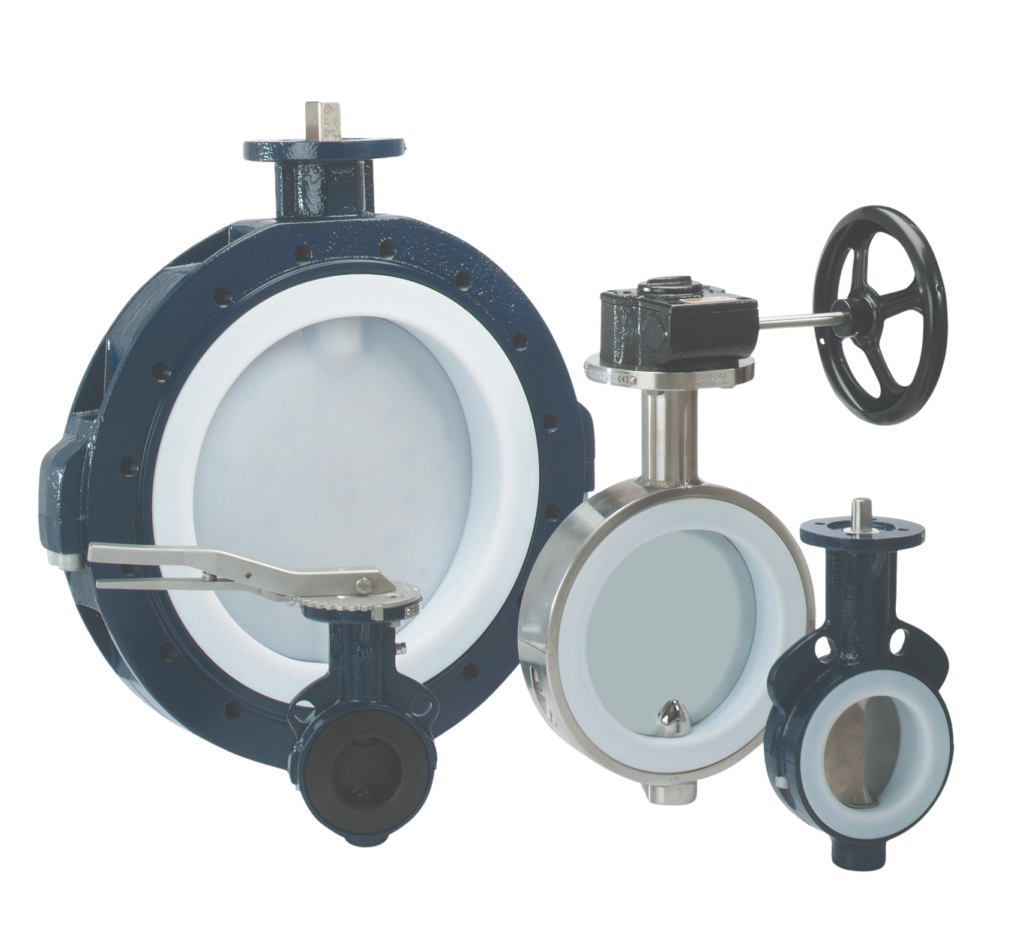

PTFE lined butterfly valve

The ChemValve-Schmid butterfly valve CST is the world’s leading modular PTFE lined butterfly valve.

The PTFE lined valve is produced to the highest quality standards for the safe handling of aggressive media. It is designed for the use with highly chemical media and is therefore used in almost all industries.

Spherical structural elements reduce friction and therefore increase the service life.