Filter the results

Showing 7–12 of 160 results

Metal seated DIN gate valve

“Metal seated RT Valvole gate valves in cast design are used when minimal pressure drop and/or a bi-directional ON/OFF operation is required.

All standard gate valves have a “”full bore”” because the wedge is completely retracted in the open position. This ensures minimal pressure drop.

Design:

* The housing material is made of cast steel.

* The valves have a bolted or pressure seal bonnet (for higher pressure) to achieve minimal turbulence and flow restrictions.

* Fixed, flexible or split wedge types are available.”

Wafer type swing check valve

The check valve CSC / CSCF offers efficient performance in a small space.

A robust shaft and a defined end stop guarantee an above-average service life. The angled shaft seat ensures improved seat tightness even at low pressures. The valve can also be equipped with a spring that supports the closing process. The large number of turns of the optional spring prevents overloading and guarantees long-lasting durability.

The check valve CSC / CSCF can be used in all industrial processes with liquids, gases and steam.

DIN safety relief valve high pressure

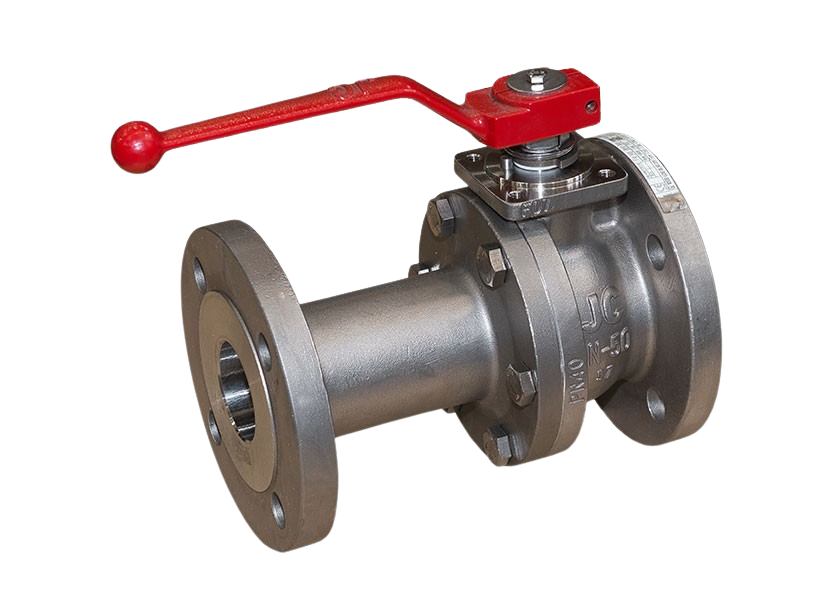

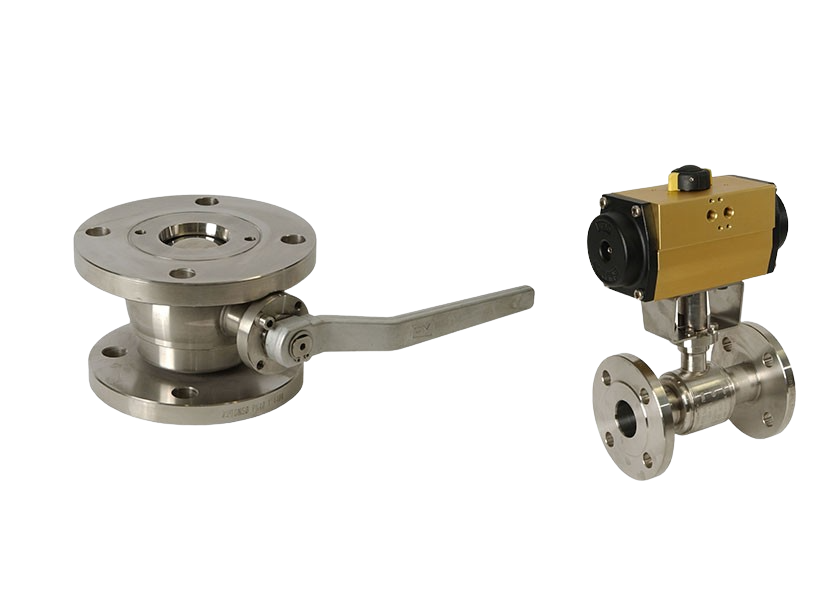

Soft seated, no dead space, fully welded ball valve

“Soft seated, fully welded, minimized cafity flanged ball valve with various approvals.

Due to its design, the fully welded ball valve can also be supplied as a bottom outlet valve.

The connection ends can be designed to suit the customer’s requirements. In addition, many other design options can be selected. “