Filter the results

Showing 115–120 of 160 results

Piston check and piston closing check valve, forged, metal seated

Wakmet piston check valves made of forged steel prevent the backflow of medium into the pipe. The check valve can also be used as a shut-off valve to open and stop the flow.

Depending on the model, the temperature ranges extend up to 530°C or 670°C (up to ≤ 200°C for PTFE).

Wakmet metal seated piston check valves are mainly used in the energy sector as well as in the pulp and paper industry. Depending on the type, they are suitable for media such as water, steam, non-aggressive and non-toxic media as well as some also for gas, fuel and sea water.

Plastic ball valve

The plastic CEPEX ball valves can be used both to shut off and control liquids.

The ball valves made entirely of plastic bring advantages in terms of resistance to chemicals. The EXTREME series is designed for special requirements and can therefore be used in steel plants, chemical plants or the oil industry.

The plastic ball valves can be operated either manually or also automatically. The model is available in a wide variety of plastics (PVC-U, CPVC, PP-H, PVDF and ABS).

Plastic butterfly valve

The CEPEX plastic butterfly valves can be used to shut off and control liquids.

The valves made entirely of plastic have the advantage that they are resistant to chemicals. The EXTREME series is designed for special requirements and can therefore be used in steel plants, chemical plants or the oil industry.

The plastic butterfly valve can be operated either manually or also automatically and is available in a wide variety of plastics (PVC-U, CPVC, PP-H, PVDF and ABS).

Plastic diaphragm valve

The plastic CEPEX diaphragm valves can be used both to shut off and control liquids.

The ball valves made entirely of plastic bring advantages in terms of resistance to chemicals. The EXTREME series is designed for special requirements and can therefore be used in steel plants, chemical plants or the oil industry.

The plastic diaphragm valves can be operated either manually or also automatically. The model is available in a wide variety of plastics (PVC-U, CPVC, PP-H, PVDF and ABS).

Pneumatic rack-and-pinion actuator

Actreg is a manufacturer of double piston part-turn actuators in aluminium housings with torques of up to 6,500 Nm.

The pneumatic rack-and-pinion actuator from Actreg offers reliable automation for valves with 90° swivel movement.

Designed and produced to withstand most applications and environmental conditions, the high precision in terms of design and quality provides long and safe operating performance.

In order to support its customers in the safe control of their processes, ACTREG relies on strict quality assurance thanks to state-of-the-art processing and testing facilities.

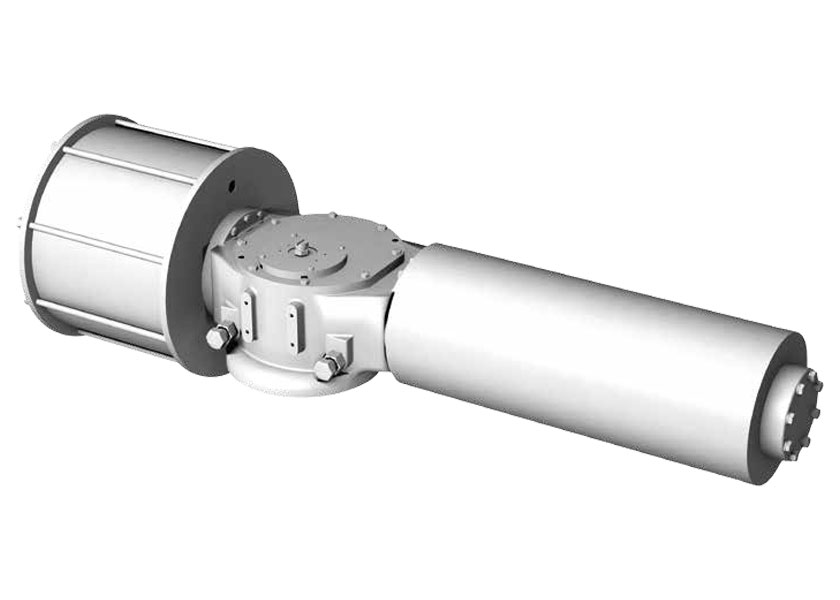

Pneumatic scotch yoke actuator

Actreg is a manufacturer of pneumatic Scotch Yoke actuators for high-performance applications up to 700,000 Nm.

The products offer reliable automation for valves with 90° swivel movement.

Designed and produced to withstand most applications and environmental conditions, the high precision in terms of design and quality provides long and safe operating performance.

In order to support its customers in the safe control of their processes, ACTREG relies on strict quality assurance thanks to state-of-the-art processing and testing facilities.