Filter the results

Showing 25–30 of 160 results

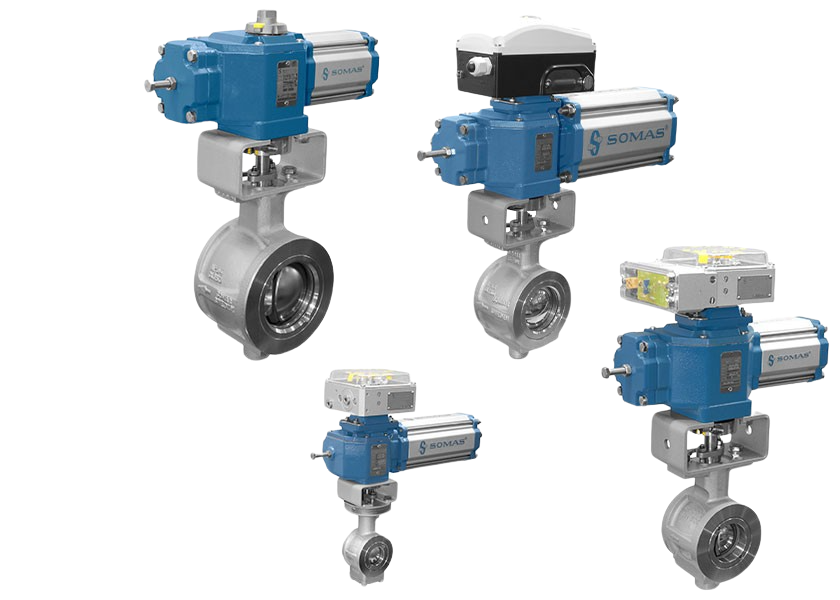

Ball segment valve, wafer design, short face-to-face dimension

“The unique system of a shaft with a clamping coupling was developed by Somas for backlash-free torque transmission and enables extremely precise control behaviour.

The Somas ball segment valves type KVTW with a centrically mounted shaft and type KVXW with an eccentrically mounted shaft are produced in a wafer version. The D-version of the valve is produced with a short length.

The valve is also produced in the A-version with the standard length (see Si-113).

The valve body of the wafer type ball segment valves is produced in one piece. The spring seat is available in three material alternatives (PTFE, PTFE 53 and HiCo [high cobalt alloy]).”

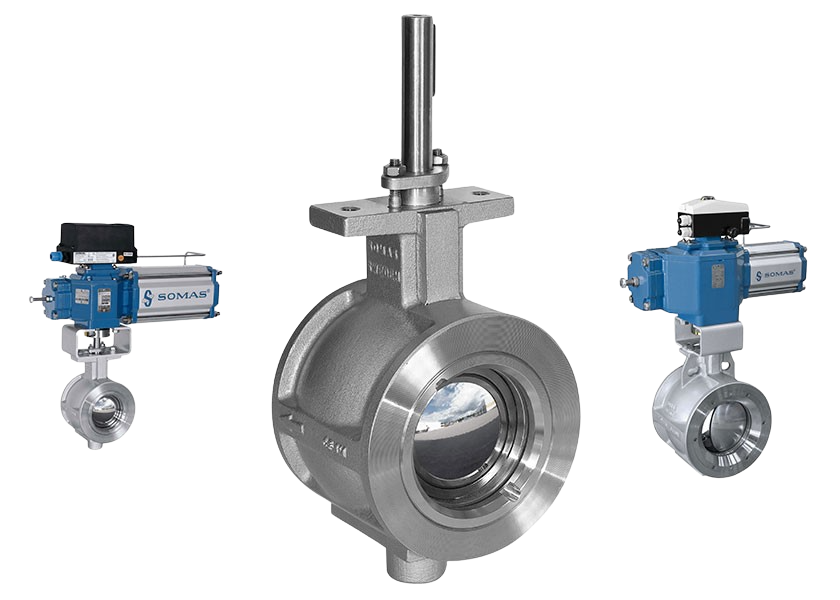

Ball segment valve, wafer design, standard face-to-face dimension

“The unique system of a shaft with a clamping coupling was developed by Somas for backlash-free torque transmission and enables extremely precise control behaviour.

The valve body of the Somas wafer type ball segment valve KVTW-A / KVXW-A is produced in one piece.

The spring seat is available in three material alternatives (PTFE, PTFE 53 and HiCo [high cobalt alloy]).

The type KVTW with a centrically mounted shaft, as well as the type KVXW with an eccentrically mounted shaft are produced in a wafer version. The A-version of the valve is produced in the standard long lengths typical of the market.

The valve is also produced in the D-version with a shorter length (see Si-114).

“

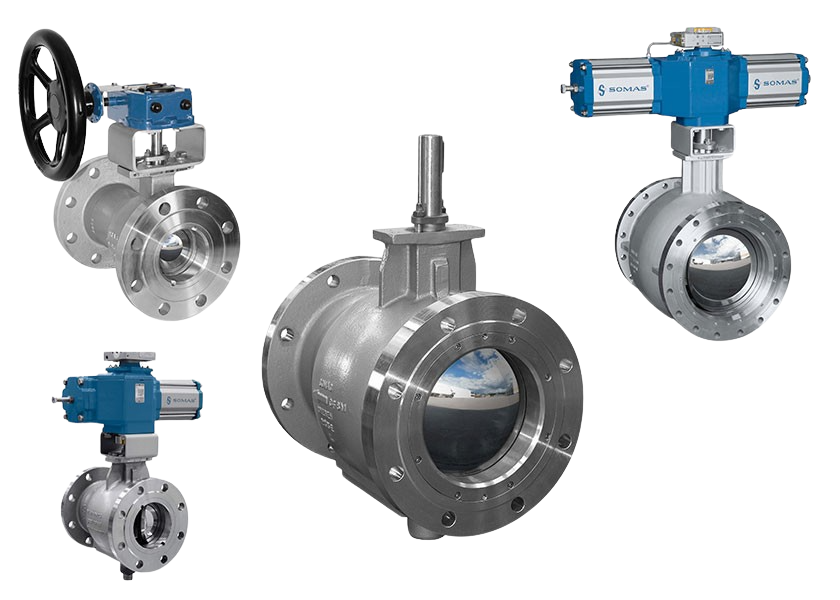

Ball segment walve, flanged design

“The Somas ball segment valve type KVTF is a flanged ball segment valve with a centrically mounted shaft and the KVXF has an eccentrically mounted shaft.

The valve housing consists of one piece and has a full bore. The unique system of a shaft with a clamping coupling was developed by Somas for backlash-free torque transmission and enables extremely precise control behaviour”