Filter the results

Showing 55–60 of 160 results

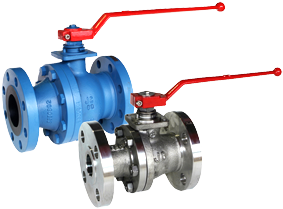

DIN flanged ball valve, short pattern, floating

“The JC Valves flanged ball valve type 516 / 540 is a floating ball valve according to DIN with a short DIN face to face length.

The standard version of the ball valve includes a anti-blow out stem, an antistatic device, a pressure balancing cavity hole and a “”live loaded”” packing.

A large selection of materials makes the soft seated, floating DIN flanged ball valve flexible to use.

With a wide range of approvals (Fire Safe, Fugitive Emission, ATEX, TRCU, CRN, SIL 3, and many others), it can be used in virtually all industries. “

DIN gate valve, small body metal seat

The BFE (Bonney Forge) metal seated, small shut-off gate valve has an outside screwed rising stem, solid wedge and flange connection.

The gate valves are forged and used for non-aggressive liquids, steam and gas.

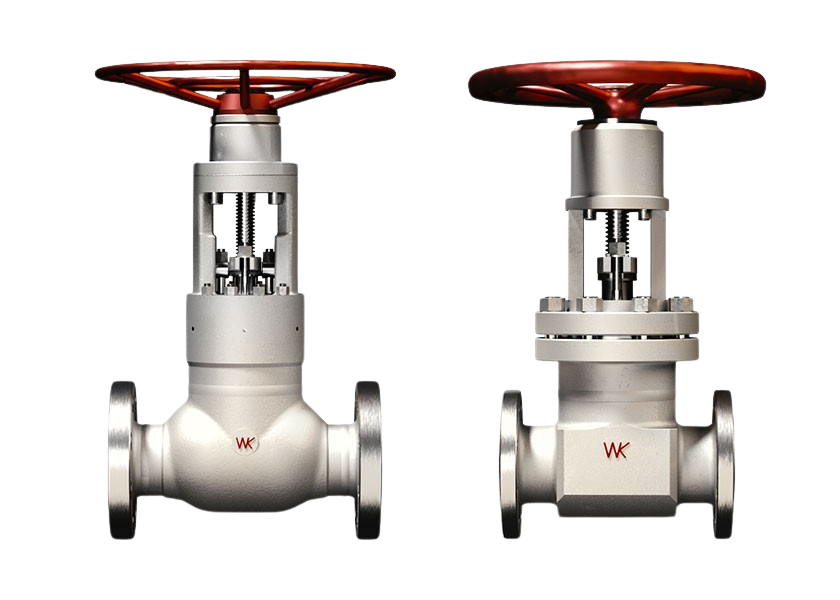

DIN high pressure, double plate wedge gate valve

The forged welded design of the metal seated DIN high-pressure gate valves are made of forged steel with a gland seal or bellows seal prevents material defects such as cracks or porosity.

This type of design ensures that non-metallic impurities are eliminated or excluded.

Wakmet protects the valve against overpressure with a safety valve unit. This type of construction allows easier isolation of the gate valve and direct access to the preset safety valve.

Axial bearing for easier opening/closing of the valve.

This valve is mainly used in the energy sector and in the area of the pulp and paper industry.

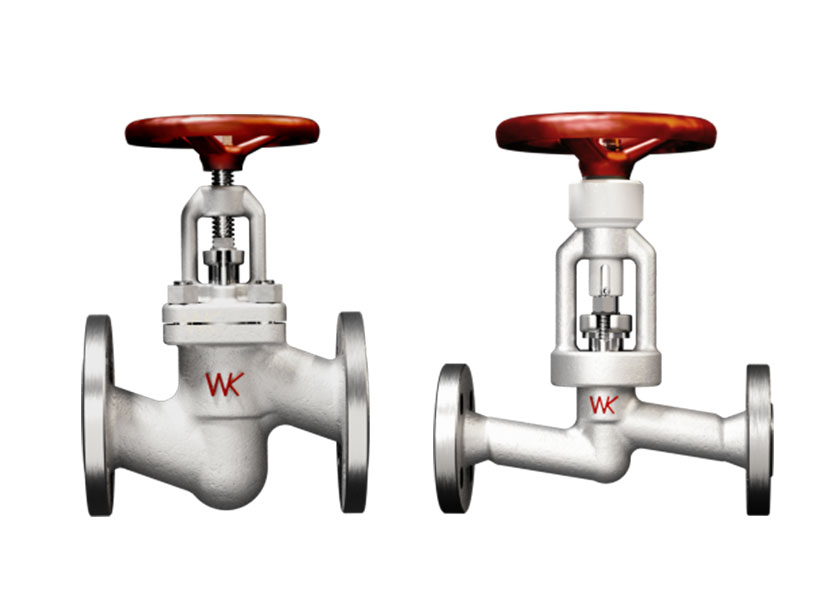

DIN on/off and control globe valve

“Shut-off control valve with a pressure balanced cone (from DN200), linear flow characteristics and a position indicator.

Available with a gland seal or bellows seal.

The valve can optionally be designed with a control cone or without oil and grease.

For nominal diameters from DN15 – DN400.

Can be used in temperature ranges of -60°C to +550°C depending on the choice of material. “

DIN on/off and control globe valve, “stellite” version

DIN on/off and control globe valve, forged with gland seal or bellows seal

“The Wakmet metal seated (Type 218 / 218R / 218M / 412 / 422 / 412M / 422M / 530 / 530M / 648M / 649M) globe and regualting valves made of forged steel with a gland or bellows seal, have a one-piece housing and are available with or without a control cone.

The monolithic design allows 100% tightness in both flow directions. The valves are mainly used in the energy sector as well as in various areas in the pulp and paper industry.