Filter the results

Showing 1–6 of 16 results

Ball check valve

The Erhard ball check valve offers backflow protection based on the ball check valve operating principle. In the open position, the sealing ball is pushed out of the flow cross-section by the medium. The Erhard ball check valves are particularly suitable for use in the waste water sector where there is a high risk of clogging.

Advantages:

Erhard ball check valves are resistant to dirt and are extremely maintenance-friendly as the valve works without mechanically moving parts. In addition, the ball check valve has low flow resistance in the open position.

Metal-to-metal seat wafer style tilting disc check valve

“The Orbinox metal seated check valve type RM is a robust tilting disc check valve with an oblique seating angle. It is used in all industries, but mainly in the pulp and paper, water treatment and food sectors.

In addition to the short length, it is characterised by a low pressure drop and opening pressure. Another advantage is the reduced pressure surges caused by the quick closing action (oblique seating).

An optional spring accelerates the closing action. “

Wafer type swing check valve

The check valve CSC / CSCF offers efficient performance in a small space.

A robust shaft and a defined end stop guarantee an above-average service life. The angled shaft seat ensures improved seat tightness even at low pressures. The valve can also be equipped with a spring that supports the closing process. The large number of turns of the optional spring prevents overloading and guarantees long-lasting durability.

The check valve CSC / CSCF can be used in all industrial processes with liquids, gases and steam.

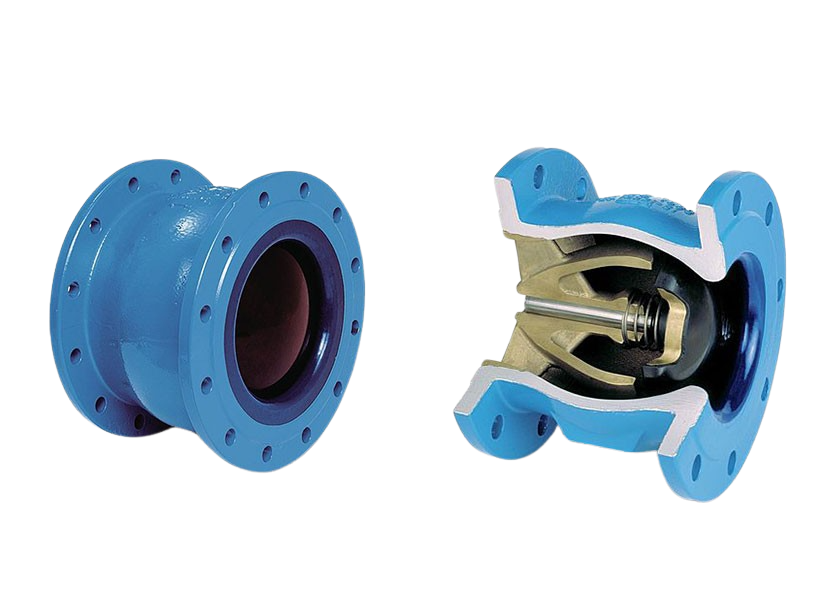

Non slam nozzle check valve

ERHARD nozzle check valves are designed for universal use and are particularly economical check valves for untreated and potable water as well as purified waste water due to their design.

Special features include the ultra-low pressure loss due to optimised flow cross-sections, a flow-efficient valve disc and valve stem gasket, as well as optimum hydraulic behaviour with short closing travel to minimise pressure surges.

Dual plate check valve

The ChemValve Schmid dual plate check valve has an eccentric disc and a wafer design.

The flow-friendly design reduces the pressure loss in the system and therefore the energy requirements of the plant.

Another advantage of this valve is that no gland is required due to the design and so it is impossible for the medium to escape.

The dual plate check valve is used in all industrial processes involving liquids, gases or steam.