Here you are

on the right track!

Whether a district heating plant and district heating transfer station, cogeneration plants, fossil power plants, nuclear power plants or district cooling plants – steam and high pressure are the main focus in all energy production processes.

In our broad portfolio of shut-off valves, butterfly valves, ball valves and other valves, we find not only high-quality solutions for these requirements, but also the right products for price-sensitive projects.

Our control valves are used in both primary and secondary circuits.

Other industries also

work at high pressure.

We are well acquainted from other industries with the requirements that steam and pressure place on valves in energy technology because high pressure is also used in many other processes, such as glass plants, paper production or in the petroleum industry.

Our high pressure valve portfolio from the manufacturers JC, Wakmet and Quadax© are perfectly tailored to this type of environment.

Control is better.

Our high-quality control valves do not permit unwanted process fluctuations. They react immediately and reliably in the event of deviations in terms of volume or temperature changes, even in the most difficult conditions. We choose the valve with the desired nominal diameter, pressure rating, appropriate actuator and the corresponding material for your process media. Flowtec control valves therefore ensure consistent product quality during operation and also increase plant efficiency.

Our topseller for energy technology applications

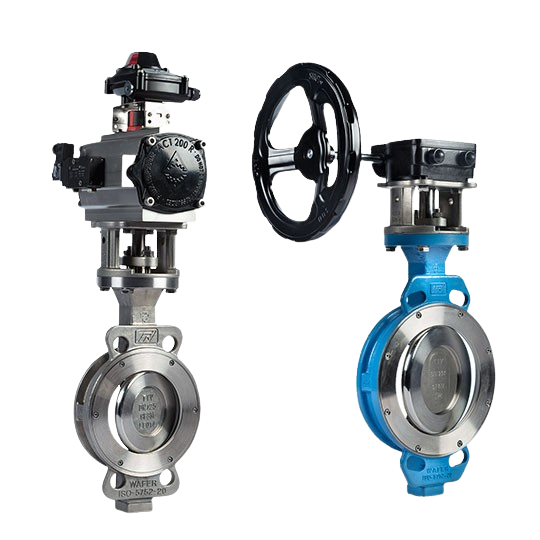

Double eccentric, high performance butterfly valve Colossus

Die Doppelexzentrische Hochleistungs-Absperrklappe bietet eine dichte Absperrlösung für die anspruchsvollsten Anwendungen.

Weitere Varianten im Programm: Konzentrische, doppelt exzentrische und dreifach exzentrische Ausführung.

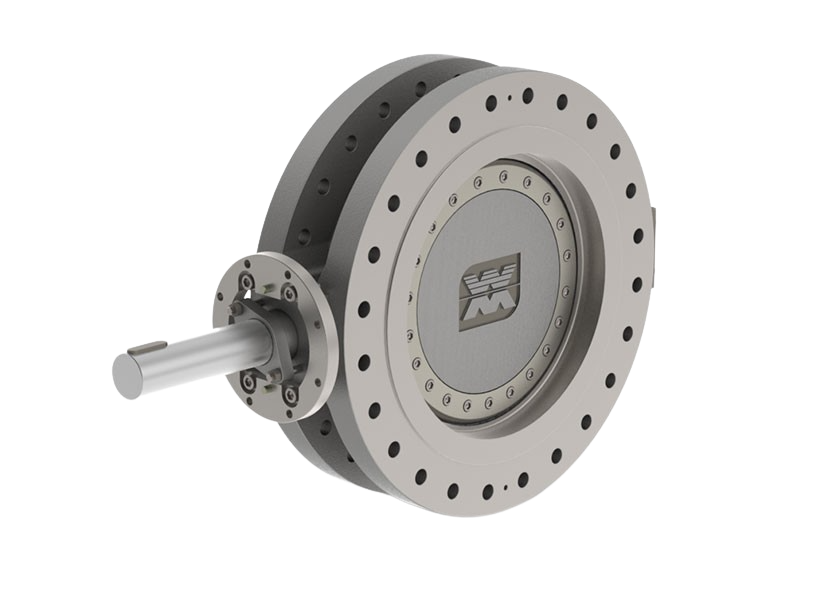

4-offset-eccentric metal seated high performance Quadax butterfly valve

“Thanks to its four offset eccentric design and state-of-the-art manufacturing technology, the Quadax valve meets the highest tightness requirements in 100% of cases.

Due to the innovative design principle, even extreme temperatures ranging from –270°C to 800°C are not a problem.

The output cone used on the butterfly is elliptical. The section under a particular angle results in a circular and therefore larger sealing area. As a result, the four offset eccentric high-performance valve is friction-free, has higher Kv values and with absolute tightness.

Available in double flange, lug type, butt weld, gate valve replacement and top entry”

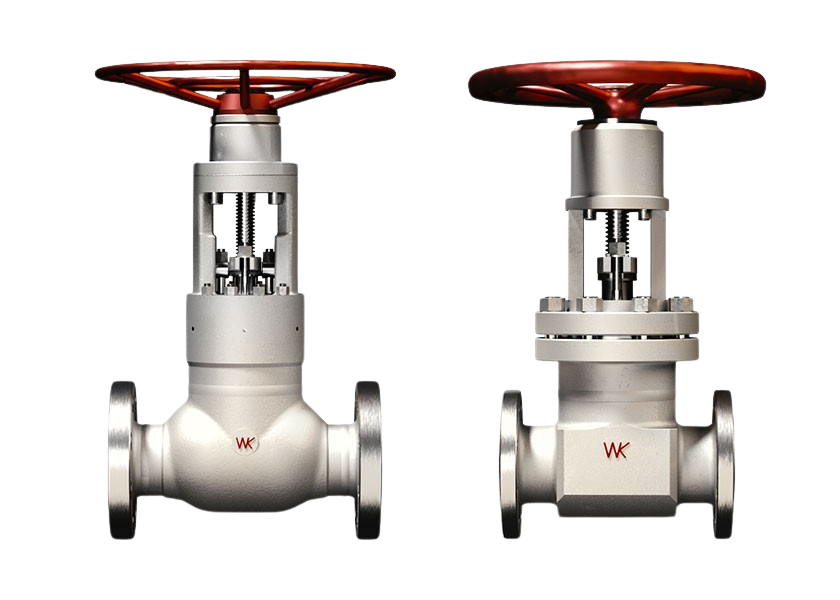

DIN high pressure, double plate wedge gate valve

The forged welded design of the metal seated DIN high-pressure gate valves are made of forged steel with a gland seal or bellows seal prevents material defects such as cracks or porosity.

This type of design ensures that non-metallic impurities are eliminated or excluded.

Wakmet protects the valve against overpressure with a safety valve unit. This type of construction allows easier isolation of the gate valve and direct access to the preset safety valve.

Axial bearing for easier opening/closing of the valve.

This valve is mainly used in the energy sector and in the area of the pulp and paper industry.

DIN/ANSI forged trunnion design, soft/metal seated, flanged ball vale

“The JC Valves ball valve series 6000 and 7000 are flanged trunnion ball valves according to ANSI or ANSI but with a DIN flange. They can be designed as both soft and metal seated valves.

The standard version of the soft or metal seated flanged ball valve in trunnion design includes a anti-blow out stem, an antistatic device, a pressure balancing cavity hole and a “”live loaded”” packing. A large selection of materials makes the ball valve even more flexible.

With a wide range of approvals (Fire Safe, Fugitive Emission, ATEX, TRCU, CRN, SIL 3, and many others), it can be used in virtually all industries. “

Flowtec Services

Don't put pressure on yourself!

We are familiar with the requirements of the energy sector and the high-pressure requirements from a wide variety of sectors. We are happy to use this know-how to support our customer in a consulting capacity.

Our broad product range enables us to combine individual complete packages tailored to the respective requirements and therefore significantly reduce our customers’ procurement costs – all valve solutions with accessories from a single source.