From customised products

to series production.

Even with a large product portfolio, there are applications where none of the valves offer a satisfactory solution. But that doesn’t mean that they don’t exist: If the use of a standard model limits the requirements, safety or efficiency of the customer process, we work with our partners to develop an innovative customised product.

It is often the case that such adaptations or improvements are transferred directly by the manufacturer into series production and therefore made available to all customers.

Long live the Junk Trap.

Why do we like to be in close contact with our customers? So that we can experience problems first-hand and develop appropriate solutions, for example, at one of our customers in the pulp and paper industry.

This customer has a Junk Trap, a heavy-duty dirt trap, which is designed to separate the reject used in the area of the pulper, high-consistency vortex cleaner or media containing solid foreign matter. The gate valves used, especially those in the lower part of the Junk Trap, are subjected to such high loads that it is necessary to replace them regularly. This results in high costs and stoppages.

Together with our long-standing partner Orbinox, a development process was started to improve the durability of the gate valves at this point.

The result is impressive – the combination of an automated CR type gate valve in the upper area and an SK type (butterfly) swing disk valve in the lower area: No contamination between the plates, no jamming or wedging, a significant increase in the service life and therefore much improved economic efficiency.

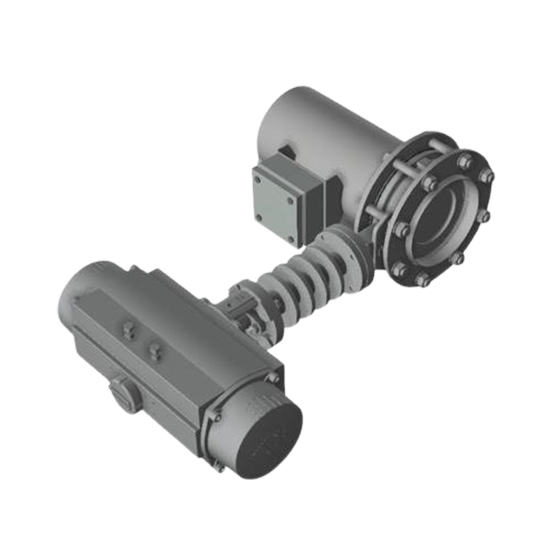

Orbinox DT type double gate bi-directional knife gate

Only the hard ones

get through.

The DT type double gate bi-directional knife gate valve from Orbinox is designed for very high consistency or concentration media or liquids and above all for heavily contaminated, fibrous media, and is therefore primarily used in paper recycling.

Its great advantage over other knife gate valves is its twice as fast closing and opening times.

The DT type gate valve must withstand high switching cycles, special loads and strong vibrations. In special cases, the service life is therefore greatly reduced.

In order to better prepare the gate valve for use in these extreme conditions, we have given it more resistance at all relevant points: a stronger hydraulic cylinder, reinforced bridges and materials on the valve plates as well as an adapted shaft diameter and mounting head. The DT type gate valve has therefore become a power package that ensures its survival even under the toughest operating conditions.

Keep a cool head.

In some cases, not only our customers get hot. But we keep a cool head and search for the best idea with our supplier. Been there, done that: The TTV – Colossus metal seated high-performance butterfly valve was turned into a survival specialist with a special shaft extension and cooling fins for use at the highest temperatures in exhaust gas applications.

We keep going

until a solution comes to light.

Customers have diverse requirements. A solution was needed for the simple operation of a low-lying butterfly valve in a pump shaft on the motorway and this solution was found in a special cardan shaft extension. Other adaptations such as special lengths, extra-long switching shaft extensions or special flanges are not an issue for our suppliers.

Whether a problem seems impossible or an adaptation for the specific customer requirement is obvious, we find a way to implement it with our partners.

Prototypen

We leave nothing untried:

You can play it safe with a prototype.

Success comes from breaking new ground. Anyone who is confronted with new process technologies or who relies on unconventional solutions to improve a process is on shaky ground because some results cannot be measured on paper in advance, but only in practice. But when valves are critical elements for process success and are redesigned for special requirements, then there must be development with scope for testing.

We give our customers this scope with the corresponding prototypes – so that they can optimise their processes for the greatest possible success. Prototypes also provide investment security in large projects with special challenges.

To submit the form, Google reCAPTCHA must be loaded. Click the button below to load the form.